It's been a couple of years since I did my first EM2 K-Swap.

After I had gotten my hands on an '04 model, my main goal was to increase its performance. Like many other car enthusiasts getting into the fascinating world of car tuning, I started with simple and cheap mods such as changing the intake and exhaust system - soon to find out that most of these mods wouldn't make my car faster, but louder.

The only modification which seemed to have a slight impact on the motor's power band was the replacement of the stock (plastic) intake manifold with the one of a D16Y8 motor. The swap created an increase in torque in the higher engine speeds and the D17 engine responded more agile.

But hours of work for a meager gain of a few Newtonmeters? It was apparent that I needed to think bigger.

During my internet research, I came across these so-called "K-Series Swaps" - swapping in one of Honda's high-performance engines.

200 hp and the rev limiter set at over 8,000 rpm.

I GOT OBSESSED.

After more internet research on required parts, costs, and the swap procedure I took the first step by purchasing a K20A2 engine from eBay.

During the next months, I encountered many obstacles while I tried to install this beast into my EM2 and get it running. If I look back to this project today, there are five things that I definitely would do differently to avoid a lot of hassle.

1) Installing the motor

It seems common sense to attach the K20 engine to a hoist, lift it, and lower it into the Civic's engine bay.

But there's one detail which I didn't think of - the K-Series motor is slightly bigger than the D17 - enough to cause a lot of frustration while trying to get it in place and attach the mounts.

Instead, the smarter approach is to raise the front of the car, place the K20 under the engine bay, and lower the car. There's much more space available and it's way easier to attach the upper mounts this way.

2) Choosing the right engine mounts

Speaking of engine mounts, this is the next point on my list which I would do differently. For my first K-Series build, I chose aftermarket K-Swap conversion mounts with polyurethane bushings. They were the only conversion mounts available back then. Although I selected the 'softest' setting, the vibrations inside the car while the engine was running were enormous.

Here's a sheet of paper dancing on the passenger's seat:

What I didn't know was that the lower mounts don't necessarily have to get replaced with the conversion mounts. Since they get attached to the subframe, you're able to fall back on stock Acura RSX, Civic Si, Civic Type-R, or any model that came with a K-Series engine.

By doing that, you would lower the vibrations which get transferred to the chassis because the stock mount's rubber bushings absorb more vibrations. On the other hand, you would sacrifice some of the stiff and direct driving responses.

If you don't mind a built-in massage seat or prioritize performance over comfort, you'll definitely be fine with the stiffer conversion mounts. For a daily driver, however, I would recommend falling back on rubber bushings.

3) Wiring in the oxygen sensor

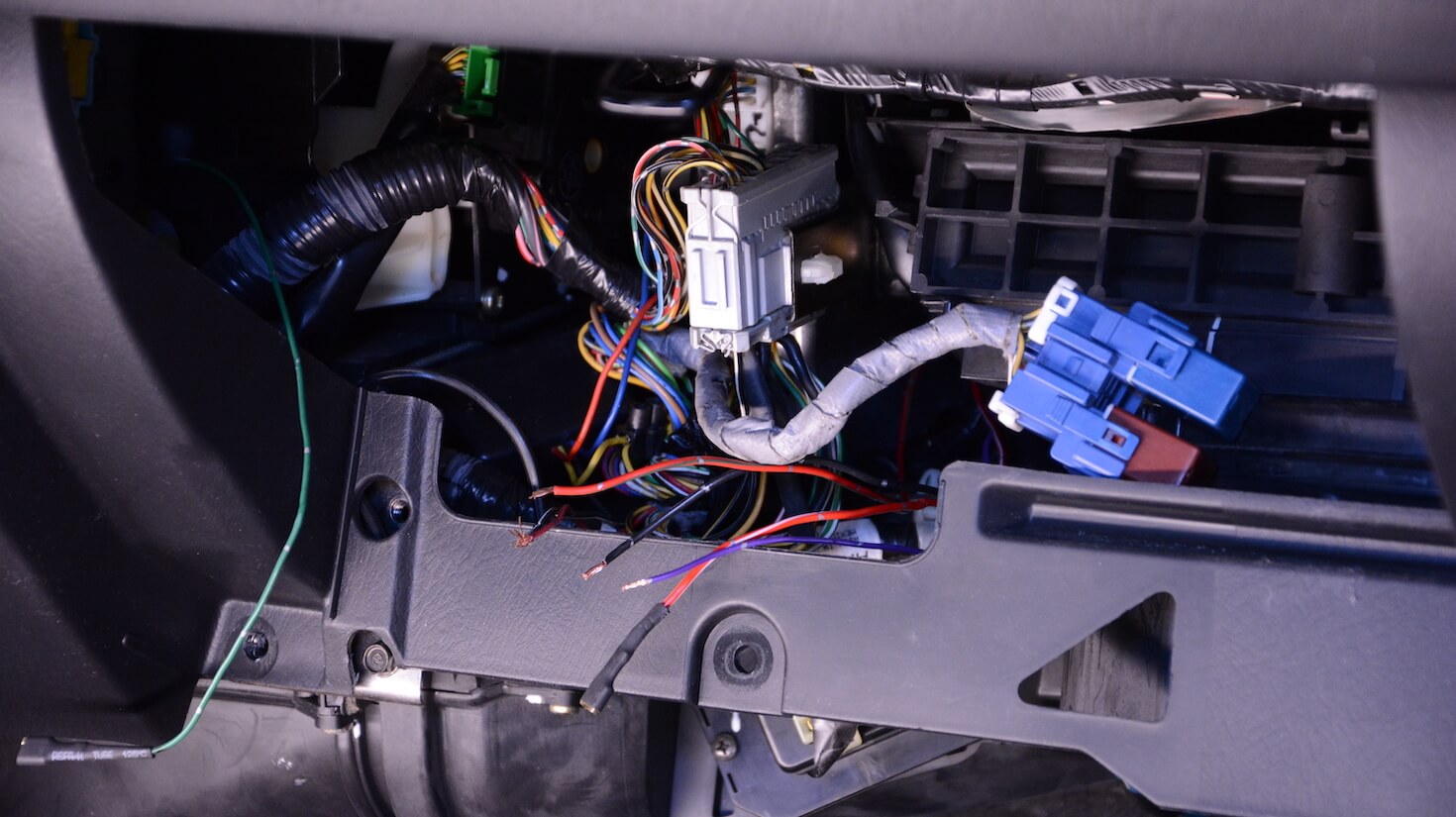

I knew that the wiring topic wouldn't be an easy one - but it turned out to be the one that caused me the most trouble.

Since the oxygen sensor wires in the Civic EM2 are not part of the engine harness, you need to wire them in separately. Fortunately, I found a brief write-up of the wiring process of an EM2 K-Swap on the internet and followed through the instructions.

Doubts had already come up when I looked at the wiring mess, and my intuition was right - the oxygen sensor wasn't delivering any measurements, but only throwing a malfunction code.

After weeks of troubleshooting, we discovered that there are differences in the sensor wiring between different manufacturing years and countries where the EM2 was sold. For example, the wiring of an EDM '04 Civic differs from a USDM '03 model.

With this fact in mind, more research and trial-and-error was done and the wiring topic was finally brought to an end.

4) Throttle Cable

If you look for the required parts for a Civic EM2 K-Swap project, the throttle cable is oftentimes mentioned as a component that needs to get replaced since it's too long to get properly mounted to the K20 throttle body.

Getting your hands on an RSX or Civic EG cable which would provide you with the right length doesn't cost a fortune. But why not save a few bucks we could spend on a more or less fancy shift knob?

We found that you can easily modify the stock throttle cable by cutting it at the right length and mount a new cable nipple.

Problem solved.

5) Engine malfunctions

The last lesson learned from my K-Swap doesn't only apply to engine swaps. This is actually a common problem people face with K-Series motors in general. Once the engine was finally running, it started a never-ending cycle of revving up and returning back to idle.

The first culprit that came to my mind was the idle air control valve (IACV). I didn't know the real mileage of the engine I swapped in, and it looked pretty dirty when it arrived at my doorstep. Good opportunity to give the valve a deep clean. Unfortunately, it kept doing the rev bouncing and only a full replacement of the valve got me a smooth idle.

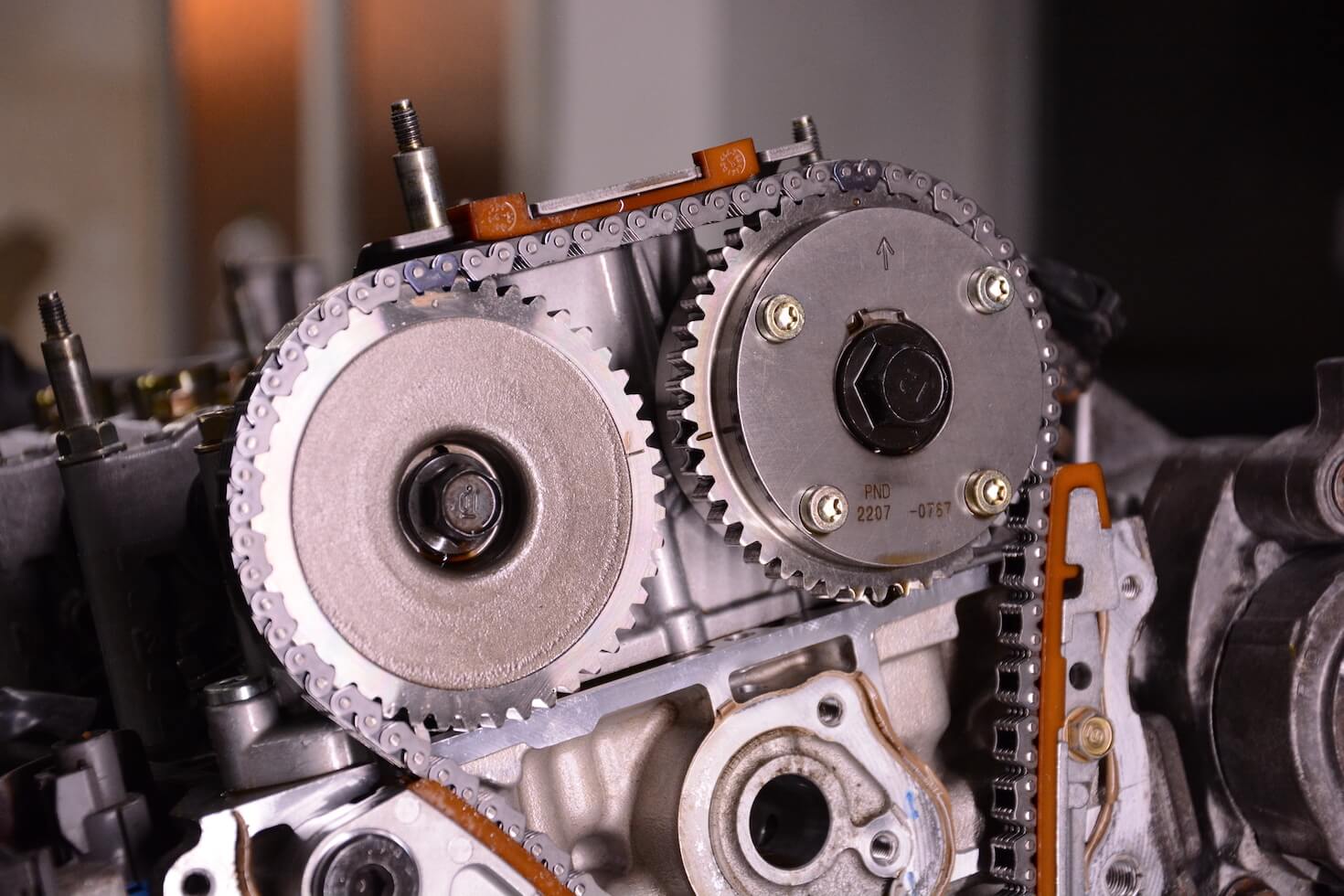

The other issue which really discouraged me when I took out the car for the first ride was the VTEC solenoid. The motor built some serious power in the lower revs, but past the 5,800 rpm mark it instantly broke in.

There were no error codes thrown, so I assumed that the solenoid was alright. We inspected the timing chain and replaced it, including the tensioner.

Although this made the engine operate a bit better, the desired VTEC kick was still missing. As with the IACV, only a replacement of the VTEC solenoid unit allowed the engine to unleash its real power.

Keep these things in mind when you start your own K-Series swap journey. It'll save you a lot of anger and frustration.

hi can you help me Mount o2 sensor? or if you can send an explanation? because I can internally inspect the car without it, I live in sweden